mGripAI

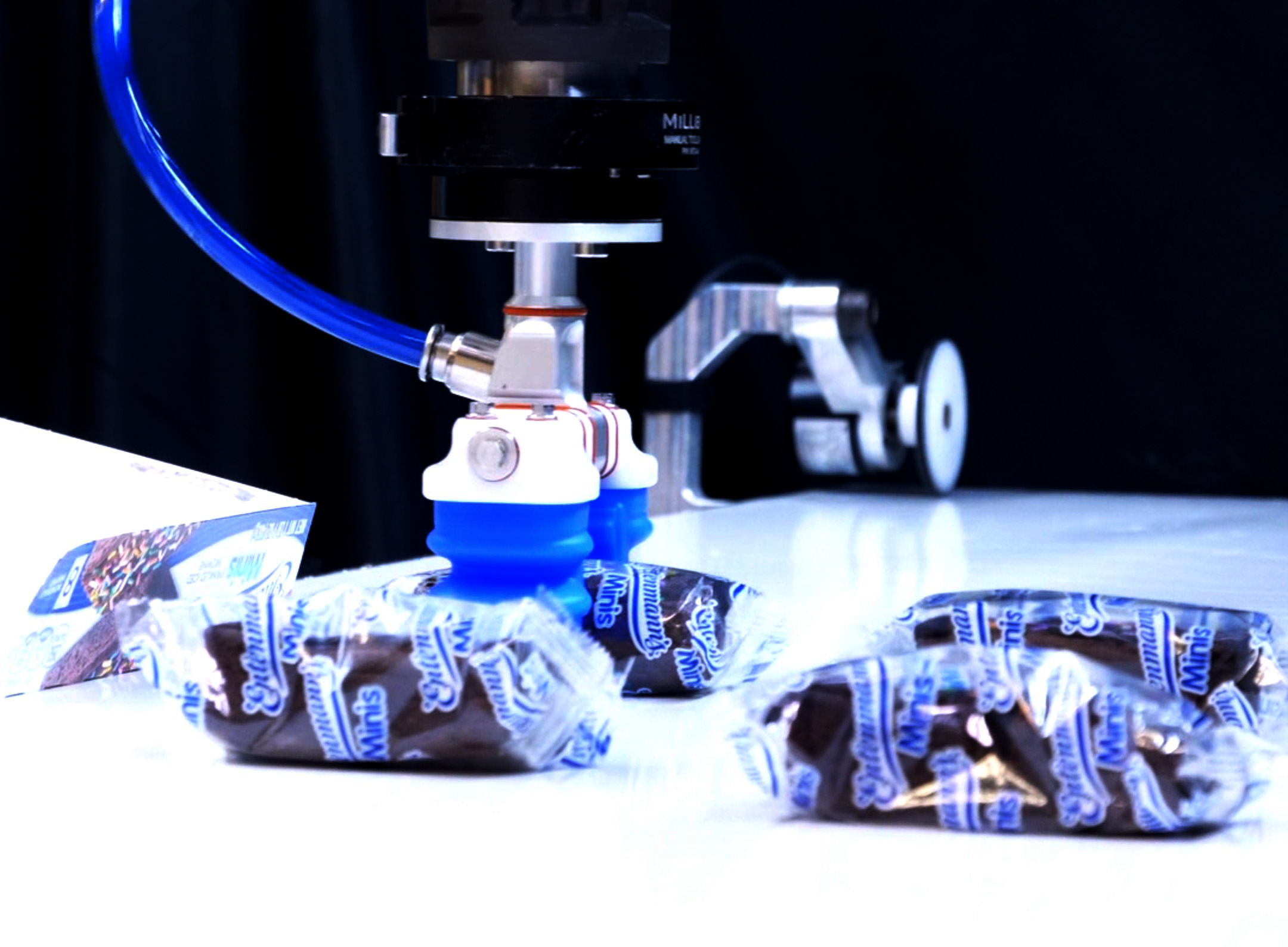

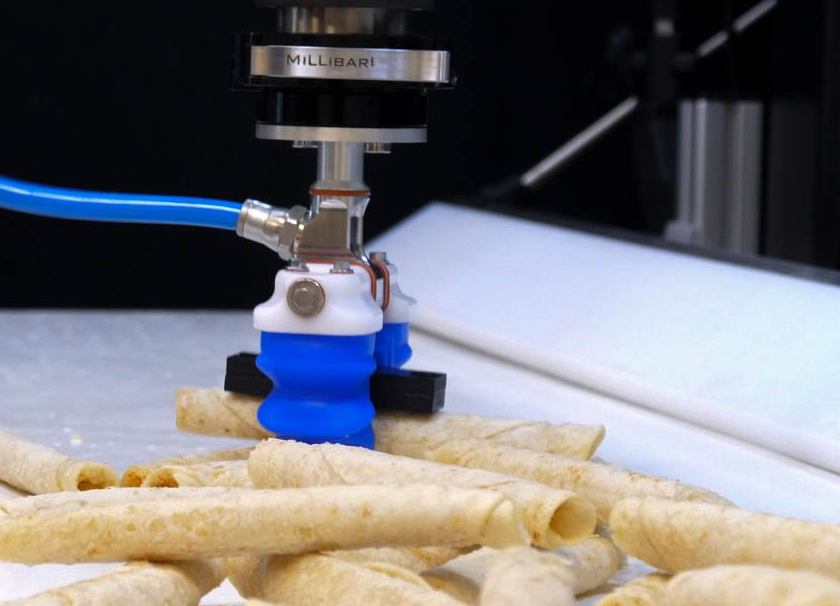

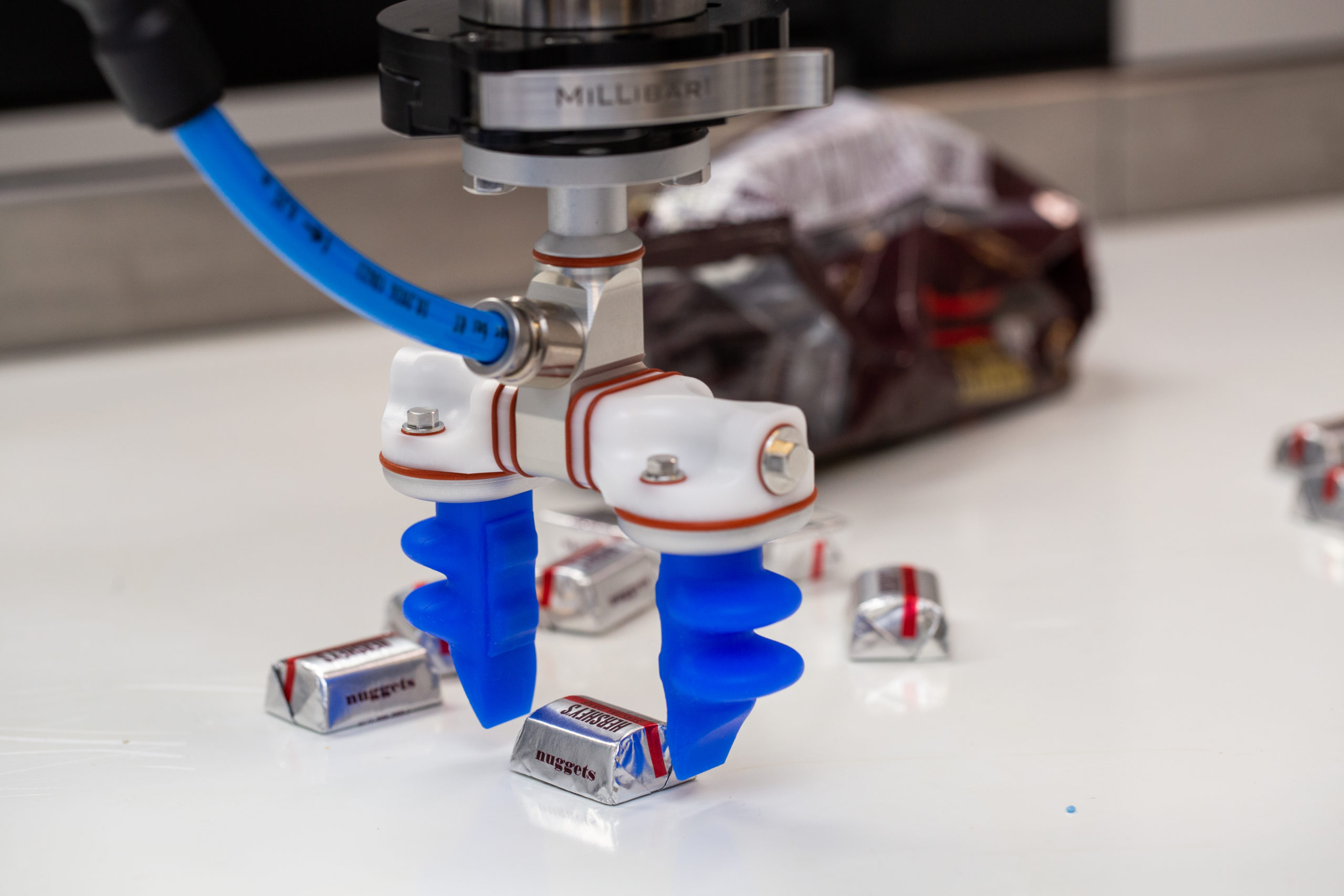

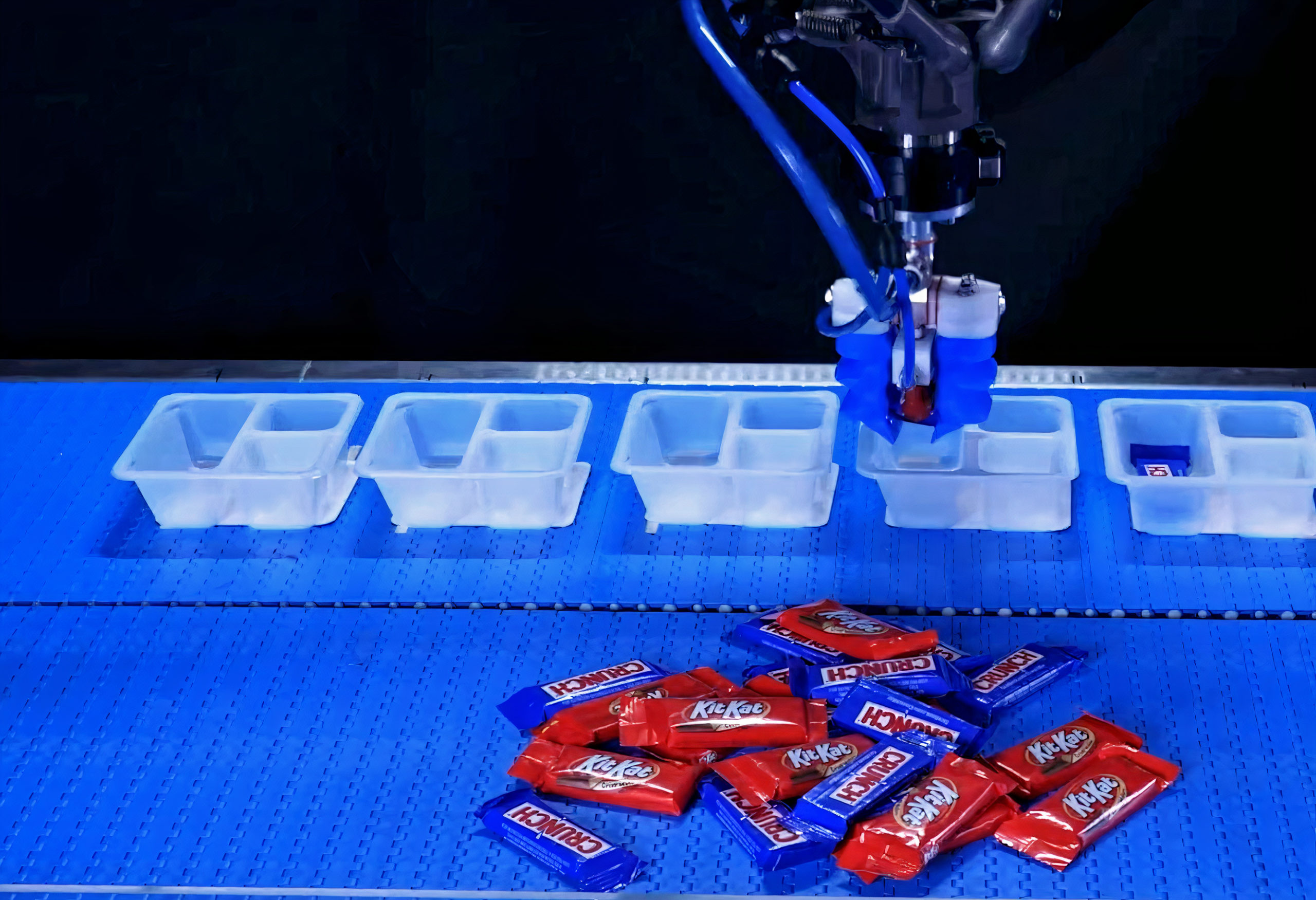

Snack and Packaged Foods Automation Solutions

The U.S. packaged food market size was valued at USD 1.03 trillion in 2021 and is expected to expand at a compound annual growth rate (CAGR) of 4.8% from 2022 to 2030. What’s driving this growth? The hectic work and life schedules of consumers across the country and the rising preference for convenience have been driving the market over the years. Food processors grappling with a shortage of labor (particularly skilled labor), more rigorous food safety standards and greater competition, are turning to robotic automation to address these challenges. Let us help.

Why mGripAI?

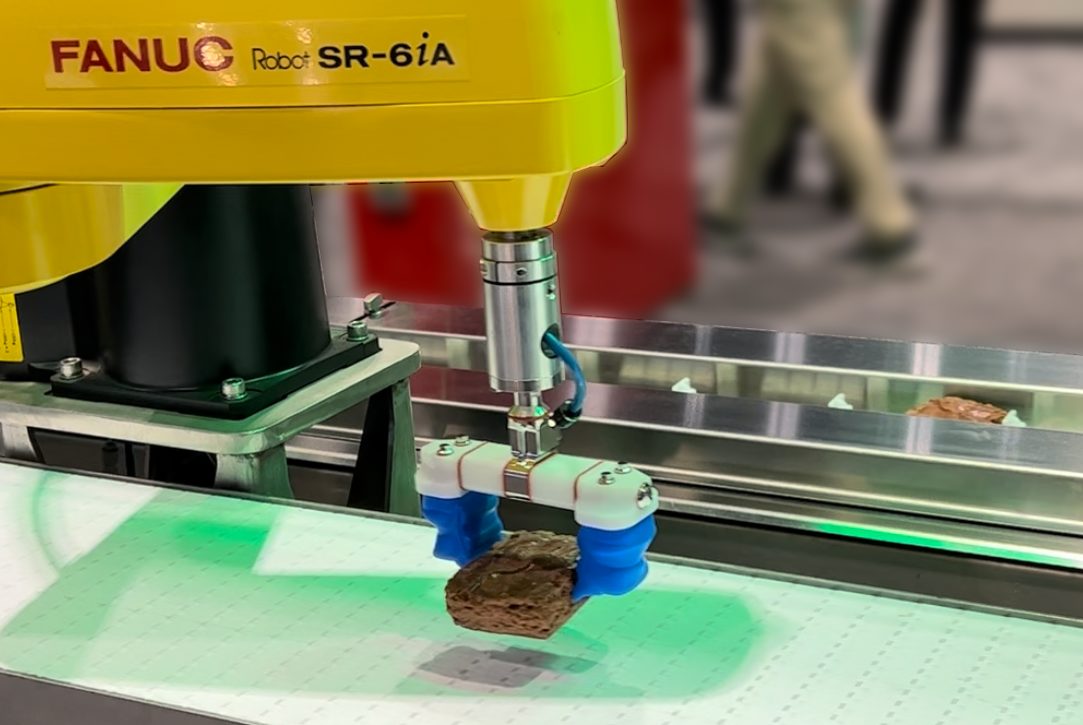

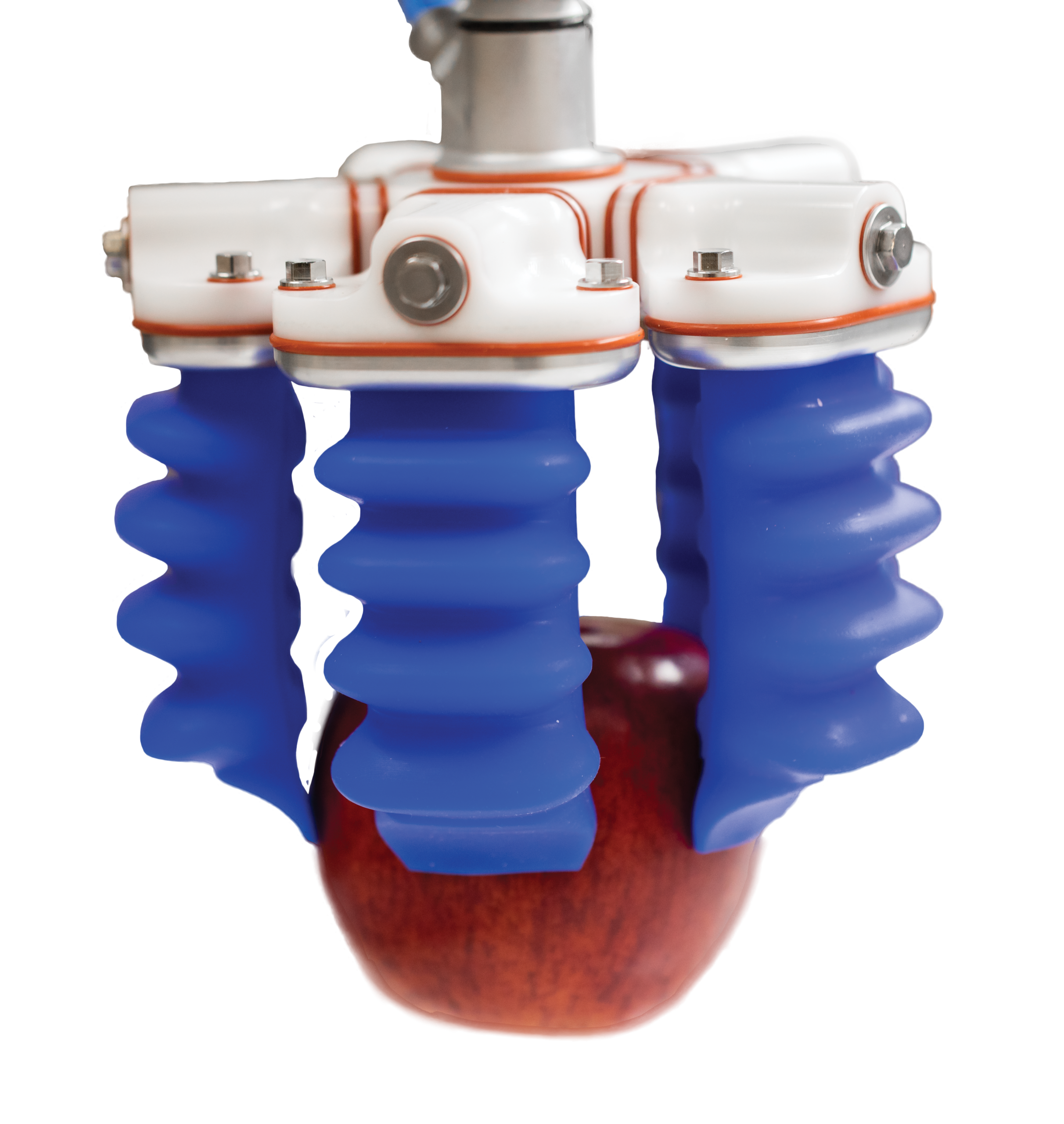

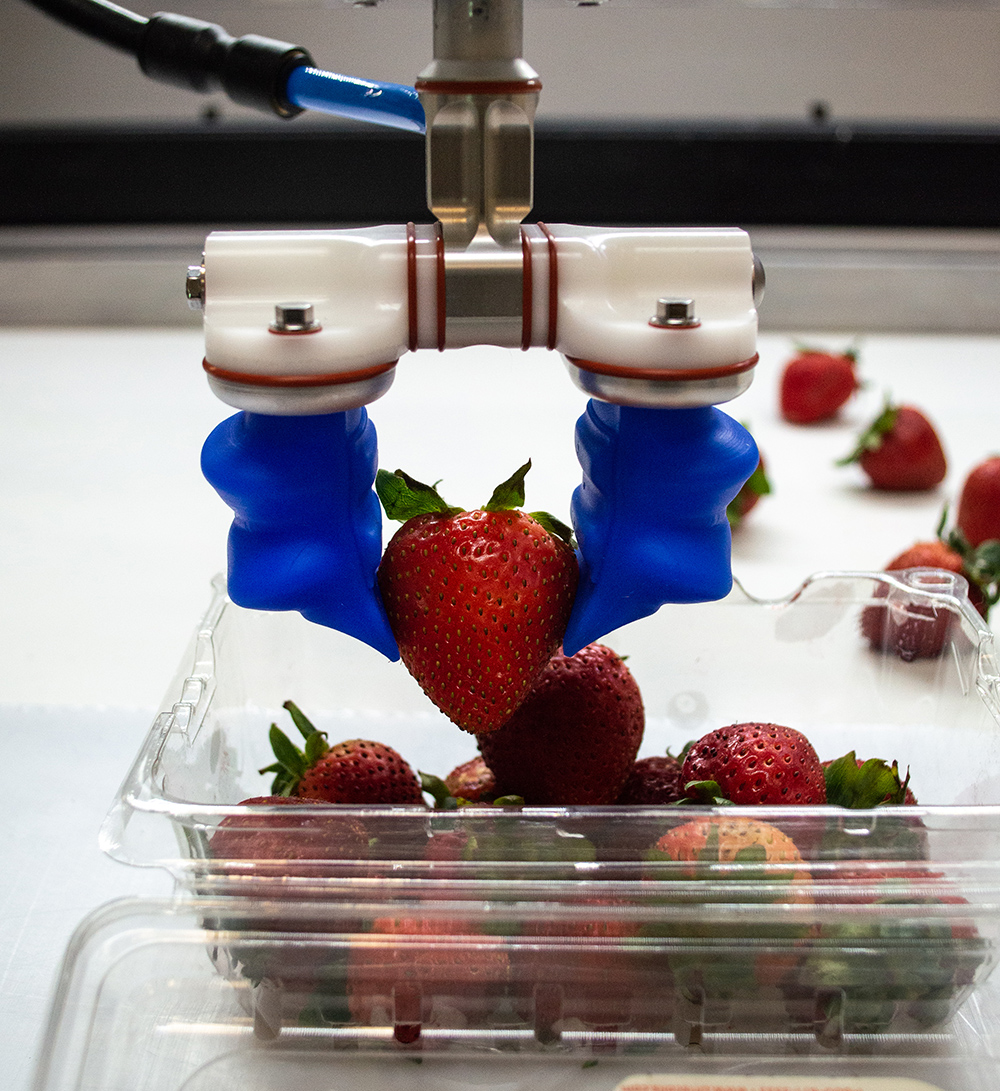

mGripAI is an easy-to-integrate automation package that combines ultra-fast 3D vision and artificial intelligence technologies with patented and proven, IP69K-rated, soft grasping to give industrial robots the hand-eye coordination of humans. This unprecedented combination of robotic “hands,” “eyes” and “brains” enables, for the first time ever, the use of high-speed industrial robots to automate bulk picking processes in the snack and prepared foods industries.

See where our high-speed automation solutions are helping food processors become more profitable and efficient in their operations.

Features and Benefits:

- Increase production by minimizing reliance on human labor

- Deliver greater throughput with high-speed picking

- Safe product handling with IP69K rating and food-grade materials

- Increase operational efficiencies

- Reduce automation footprint

- Pick delicate and variable products directly from bulk

- Reduce product damage with soft gripping

- Automate primary and secondary food processing applications

- Lower operational costs

- Easily integrates with all industrial robots

Video Library

Image Gallery

CASE STUDY

Just Born (Maker of Peeps) Automates Production Line

“Soft Robotics was able to pick up delicate marshmallow – was able to do that job and keep the same excellent quality that we had when we manually picked the objects and placed them. It enabled us to have a lot more flexibility in our process.”

—Randall Copeland, Senior Vice President of Operations and Supply Chain at Just Born Quality Confections

CASE STUDY

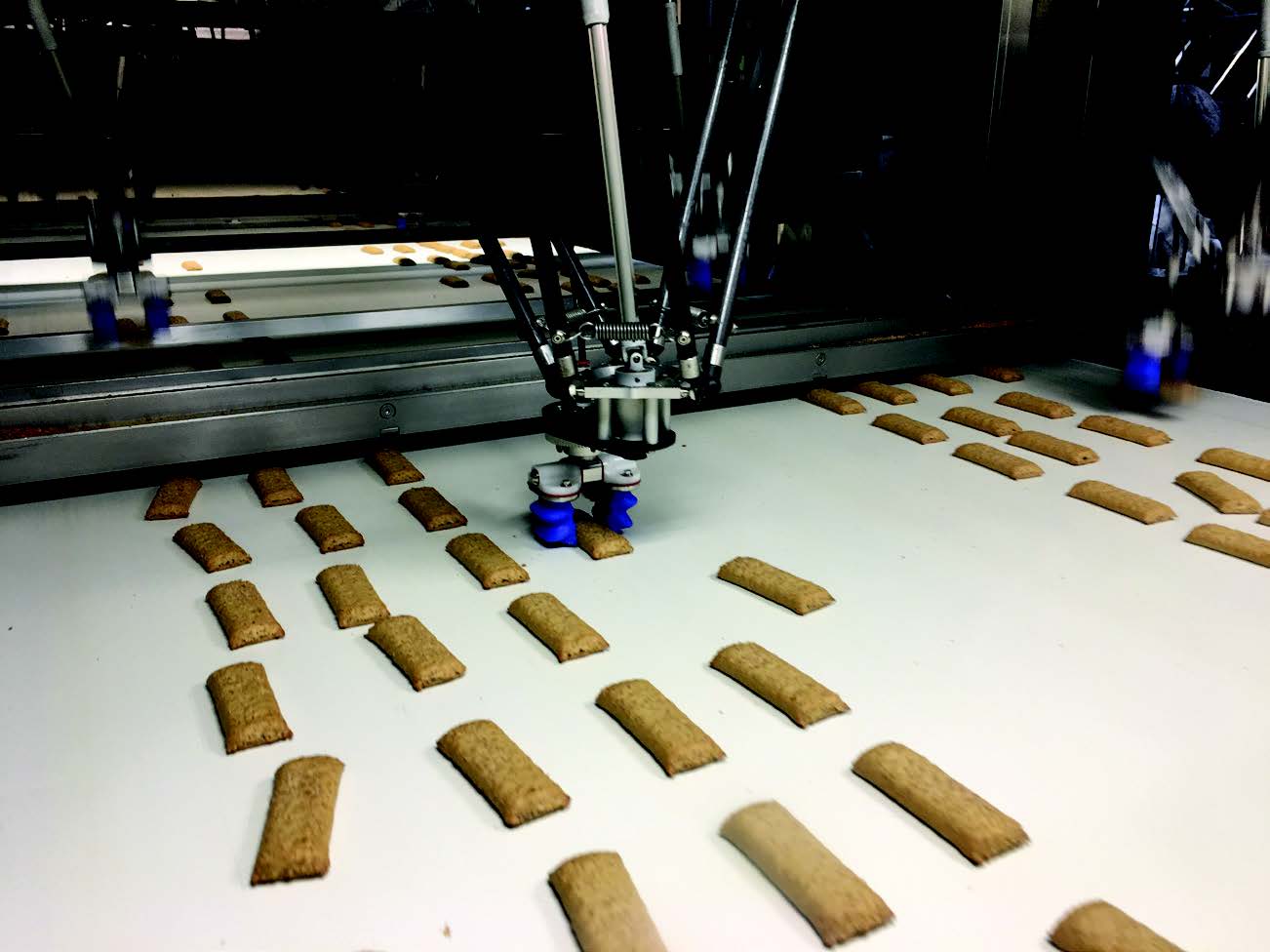

Schulze and Burch Cereal Bar Automation

“After shifting to the mGrip, we were able to increase our cycle times from up to 40 picks per minute to up to 60 picks per minute with virtually no missed or dropped picks. Based on these higher pick speeds and reliability, we were able to increase overall line speed by 50% by moving to the mGrip solution.”

—Ryan Kaminski, Senior Project Engineer at Schulze and Burch

CASE STUDY

Global Retail Pizza, Dominos, Automates Fresh Dough Production Solution Designed by ABI

Soft Robotics’ fully automates Dominos production of fresh dough including the transfer of dough balls from the rounder to shipping trays.

“Through our partnership with Soft Robotics, we were able to offer a more advanced and efficient solution to our global retail pizza client, designing a customized robotic system which allowed us to automate this challenge at high speeds.”

— Alex Kuperman, President & CEO, ABI LTD