mGripAI

The Answer for Profitable Food Processing

REVOLUTIONARY PROTEIN PROCESSING TECHNOLOGY

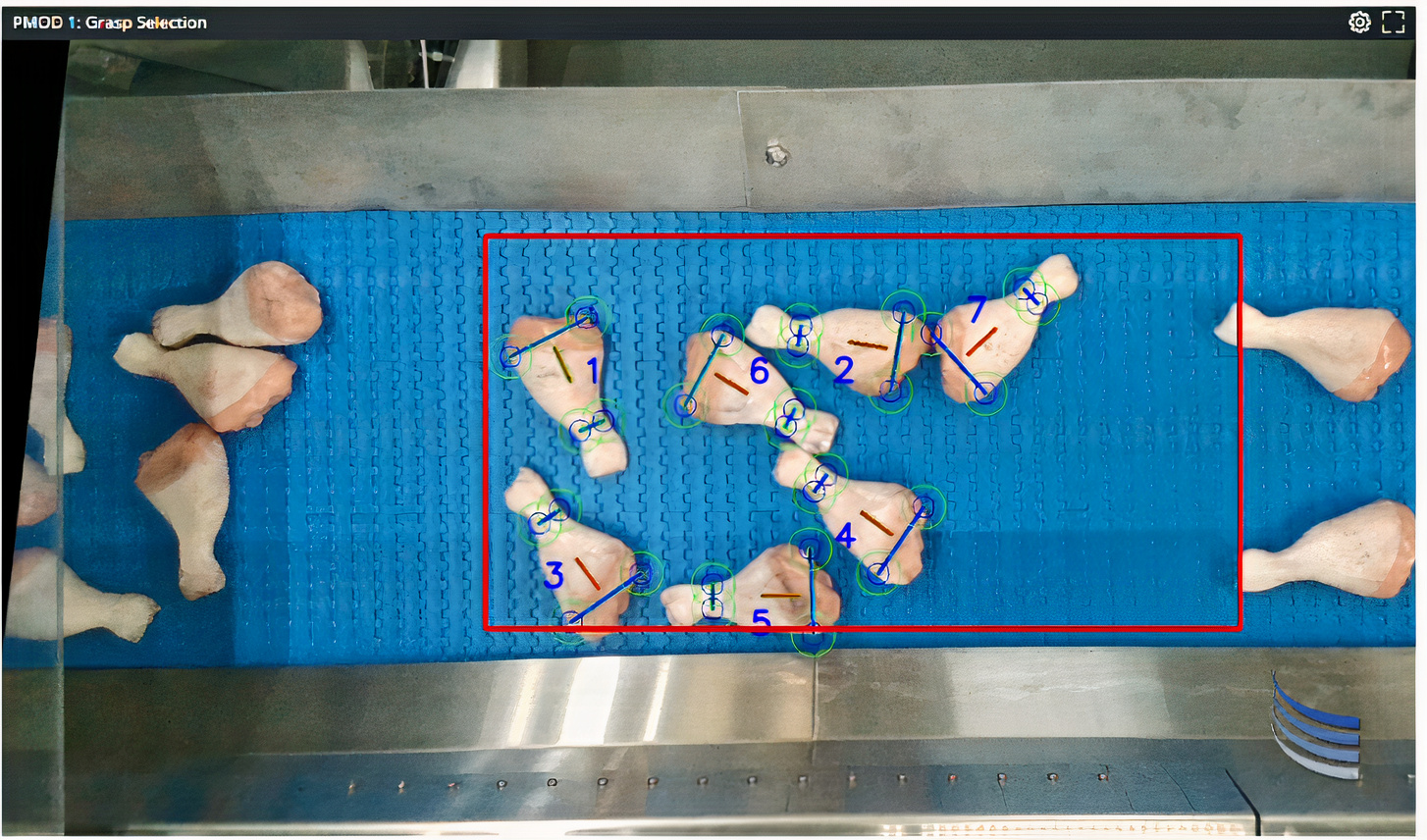

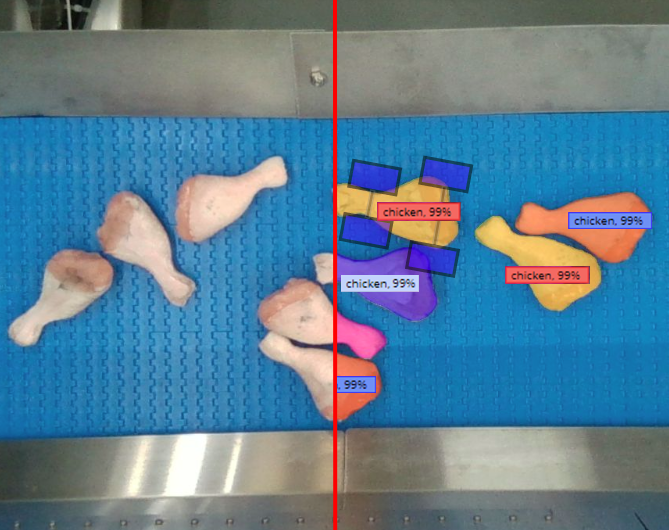

3D Vision. Artificial Intelligence. Soft Grasping.

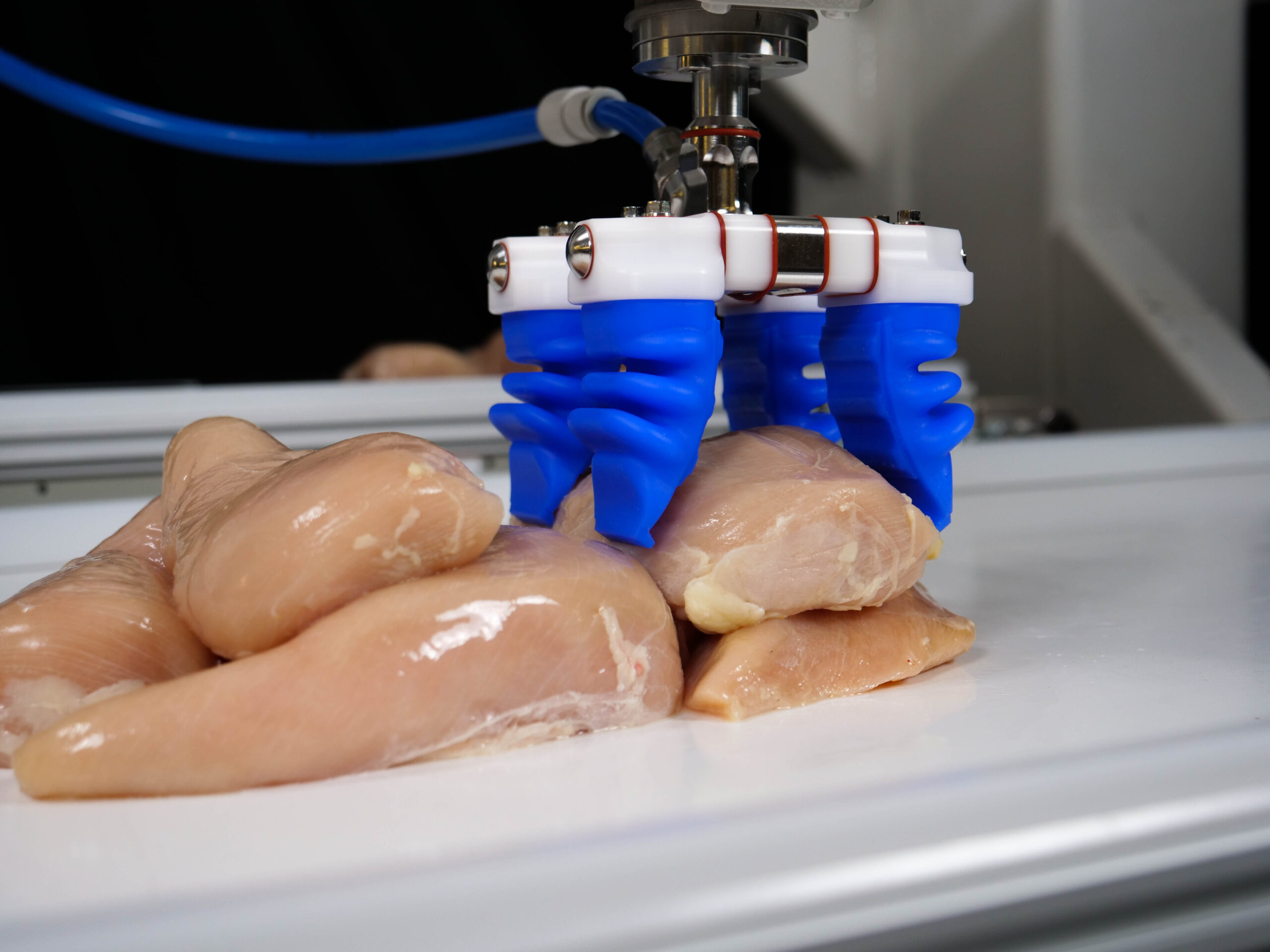

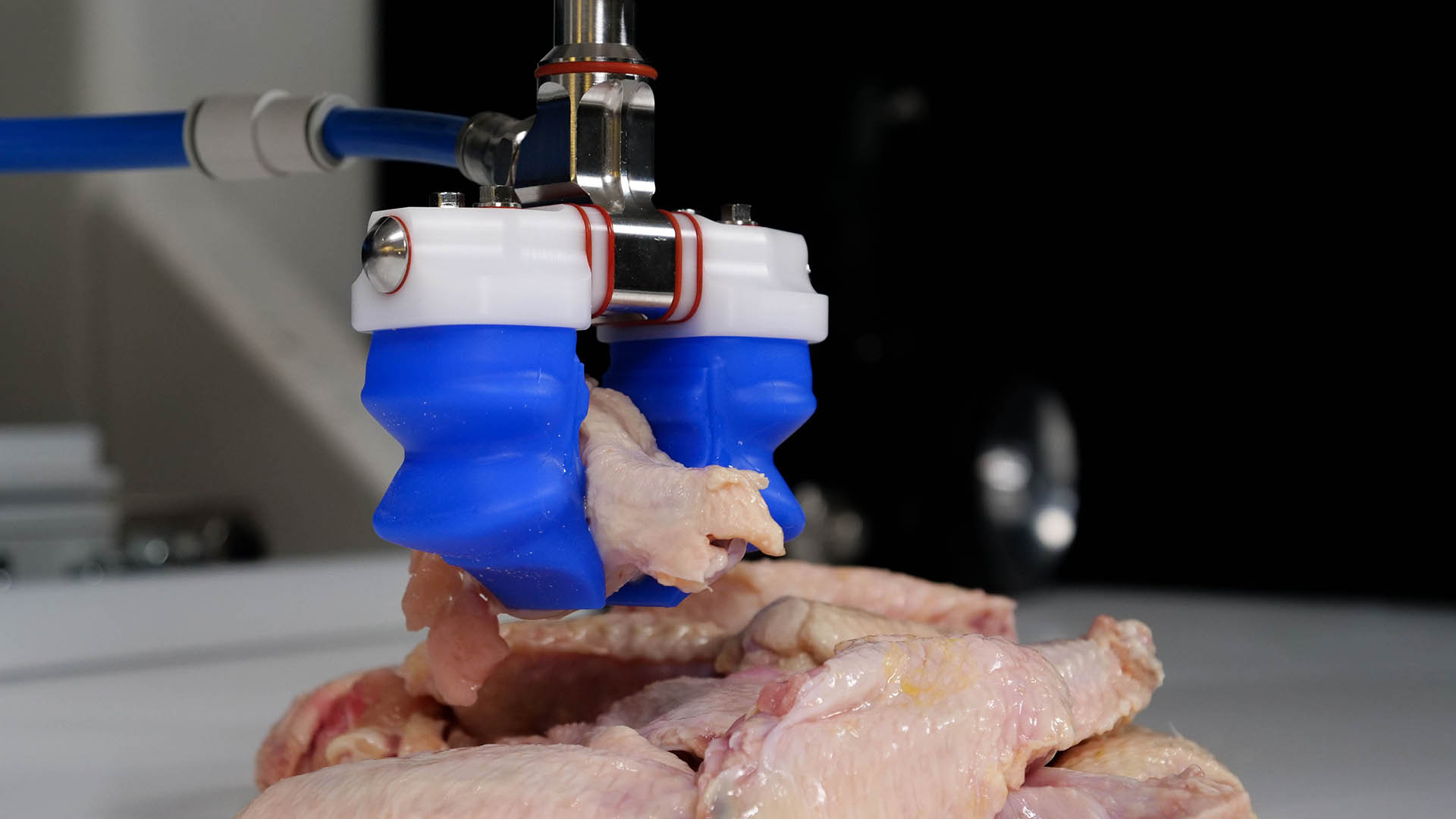

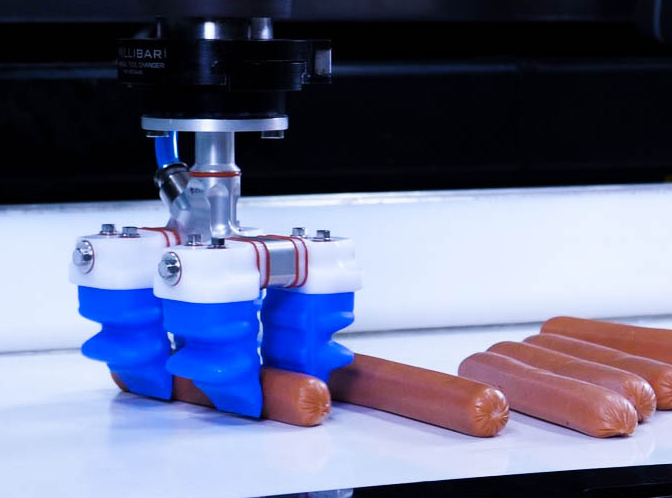

mGripAI™ is an easy-to-integrate automation package that combines ultra-fast 3D vision and artificial intelligence technologies with IP69K-rated, soft grasping to give industrial robots the hand-eye coordination of humans.

With mGripAI technology you can singulate, inspect, and pack meat and poultry products of various size, shape, weight, and form all while improving your operations—allowing you to maximize production without the reliance on human labor.

The power of mGripAI

Fastest 3D Picking System

mGripAI can operate at speeds of up to 90PPM per robot.

Reduce Product Damage

Intelligent soft grasping algorithms limit pile disruption and ensure a firm, but delicate grasp.

Handle Product from Bulk

Eliminate the burden of upstream singulation from your processing line.

Reduce Automation Footprint

Eliminate the need for large, expensive, and difficult to maintain singulation equipment and deploy robots directly in line.

Eliminate Human Touch

Reduce the risk of humans introducing contaminants to your processing line.

Wash-Down Ready

Food grade design with IP69K rating allows for clean-in-place operations.

Easy to Integrate

mGripAI combines 3D vision, AI and Soft Grasping into one very powerful picking package.

Fast. Safe. Proven.

Intelligent Automation

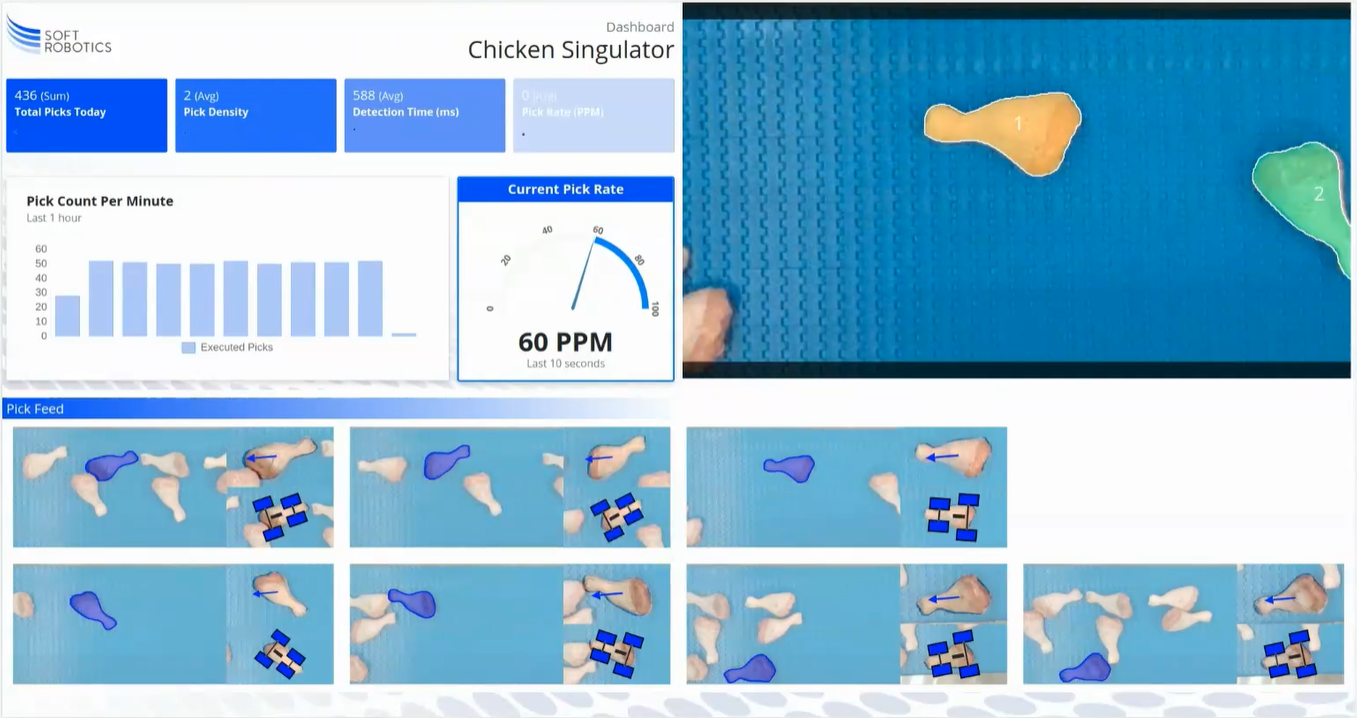

Intuitive Web-Based Tools

20+ filter and sort parameters allow any user to leverage the power of AI in picking applications.

Data with Every Pick

Optimize your application using valuable data served up from every pick.

Performance Monitoring

Data-rich dashboards keep you in the loop on system performance.

Food Processing Applications

Tray Pack

Pick, orient and pack directly to trays

Singulate for Post Processing

Feed breaders, slicers, portioners, or freezers with singulated product.

Classify and Sort

Identify and separate mixed product or remove exceptions.

Intelligence in Every Pick

Like what you see?

| Check out our protein white paper Robot Advancements Drive Efficiency, Productivity in Protein Processing.

|

|